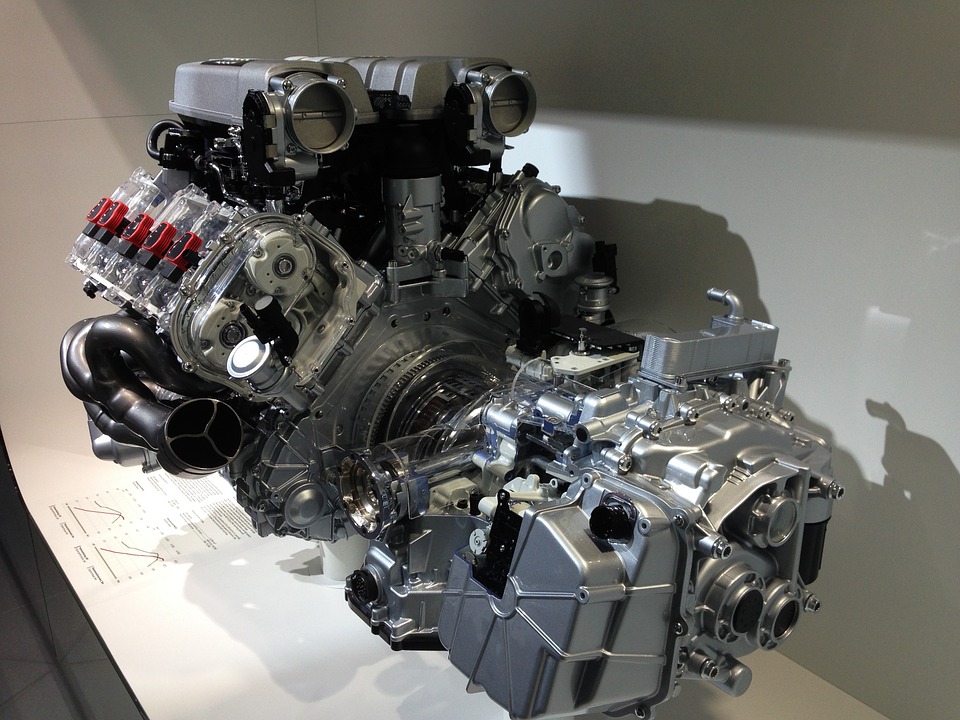

Who needs ICE engines and transmissions anymore?

In his groundbreaking 2014 book Clean Disruption Tony Seba forecasted the coming disruption to the traditional auto industry caused by an inevitable economically driven switch from ICE powered vehicles to battery powered electric vehicles. He and James Arbib later further developed these views in their 2017 book Rethinking Transportation 2020 to 2030.

Today, we find that not only have those two books’ forecasted trends and numbers been unerringly accurate, but the traditional Detroit “Big 3” manufacturers (GM, Ford, and FCA’s US-based operation, namely RAM trucks, Dodge cars, and Jeep) are just beginning to cope with the implications of Seba’s six year-old forecast.

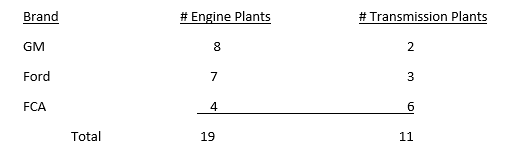

To gain some perspective on what the electric vehicle revolution means to those three companies’ operations, GM, Ford, and FCA-US currently have a total of 19 ICE engine plants and 11 transmission plants in North America (US and Canada)**. These include either engine or transmission assembly plants or plants that manufacture related component parts such as transmission housings or torque converters.

Here’s the breakdown of North American engine and transmission plants by brand:

If we assume Seba’s forecasts continue to be largely correct, and conservatively assume some 85% of those plants will be gone by 2030, then GM, Ford, and FCA-US will be closing some 26 engine or transmission plants by 2030.

According to their corporate websites, GM employs a total of 8,371 workers (salaried and hourly) in their engine and transmission plants, Ford some 13,115 workers, and FCA some 11,602 workers, totaling 33,088 workers. [I cannot explain the disparity between GM’s and Ford/FCA’s numbers – these are hard current numbers from their corporate websites.] Thus as a rough estimate, closing 85% of these plants would result in eliminating some (33,088 X .85) = 28,125 workers, assuming they were not all re-absorbed in some other parts of their company’s operations. Assuming an average pay between salaried and hourly workers of $50,000 each, the plants’ local economies would lose roughly $1.41 billion in worker incomes.

The $1.41 billion represents only the direct wage and salaries paid to those plant workers. It doesn’t consider the local tax revenue lost to each town, the number of suppliers to those plants affected, or the numbers of local businesses lost that depend on those workers for revenue and support. Nor does it consider the effect on local schools, day care centers, doctors and hospitals, and the like.

Of course if all these 30 plants close, which is more than likely given the speed of the coming electric vehicle disruption, these numbers and significant effects will be even higher. One could argue that many of these workers will be absorbed by new auto plants of these three companies or others making electrical motors and drive units, inverters, batteries, and the like. Therefore the pernicious effects of this energy/propulsion transition will not be as severe as I painted. This is probably correct. Given the simplicity of the electric vehicle battery driven drivetrain versus the complexity in parts count and technology of ICE driven vehicle components, I estimate that at best some 40% of the laid off workers can be transitioned to the new electric vehicle world — if they are willing and able to be retrained, and perhaps also be relocated.

Consequently, GM, Ford, and FCA will have 25 to 30 vacant North American plants on their hands by 2030. They might re-purpose some 10 or 12 of them during that time for the electric vehicle world as GM is doing with its Hamtramck assembly plant. So what do the three corporations and the towns/cities affected do with these old plants? Some of them may require significant environmental cleanup costs before they can be sold or even donated to any organization.

If we assume the same proportionality of engine and transmission plants to cars produced for the rest of the world, based on 2019 numbers, North American production accounts for about 17.5 million/92 million or 19% of the world’s total “car” (light vehicle) production. So if North America has to shut down some 26 engine and transmission plants over the current decade, it follows that GM, Ford, FCA (ROW) and the rest of world’s auto producers will have to close some 109 more such plants (assuming the same 85% ratio, 128 at 100%) around the globe during the same time, although some (the Germans in particular) might stubbornly hang on to producing their money losing (by that time) ICE powered vehicles.

Note that the above proportionality assumption may not be as valid for OEMs in the rest of the world as ROW OEMs tend to buy their automatic transmissions from major suppliers such as ZF and Aisin. In that case, it would be the suppliers’ transmission plants closing.

Today, conventional auto manufacturers lose money on electric vehicles. Soon, within a year or two, that situation will reverse. Battery costs will continue to drop (at about 18% per year) and electric drive train (including battery) performance will continue to increase. Additionally, ICE powered vehicles will find themselves burdened by increasingly costly environmental regulation compliance. Given these two factors, ICE powered vehicles will become permanently cost and performance disadvantaged vis-a-vis electric vehicles.

As consumers become better educated about the advantages of electric vehicles (including a lower purchase cost soon) they will be only too happy to give up the much higher operating and maintenance costs of an ICE vehicle, being urged or forced to go to their dealer for service, and their vehicles wearing out by 150,000 to 180,000 miles of use. This is contrast to EV’s lasting 300,000 to 500,000 miles and continually improving in function and value due to ongoing over-the-air (OTA) software updates.

As solar energy, battery power storage, and electric vehicles of all types replace traditional power generation and ICE powered vehicles, global society and business will face massive disruption over the coming decade. There is no better book to describe this and how to benefit from these changes than Arbib and Seba’s 2020 book Rethinking Humanity, a priceless 76 page paperback available on Amazon, or for free in PDF form at www.rethinkx.com.

It is especially important that you pass this book on to your children and grandchildren as it will help them understand and be successful in the world Seba and Arbib describe. Please read it.

** Sources: GM, Ford, and FCA corporate websites, and www.marklinks.com

Image courtesy Pixabay

Your feedback in the form of comments or suggestions are welcome in the comment window. Thank you for following my blogs on this site and for participating in my blogging community.