New EVs for US ….. Polestar 2 – Great But Problems ….. Another Steal for Elon ….. New Toyota and Panasonic Battery Plant ….. Taxpayer Cost for Europe’s Company Cars ….. Consumer Reports Discovers EV Owners Save Money!

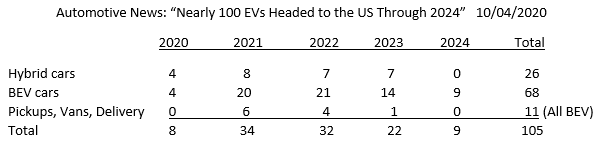

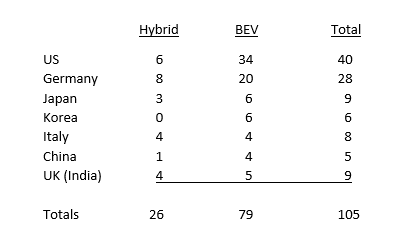

**** Automotive News had a long article recently detailing the many electric vehicles that are coming to the US market from global auto manufacturers through 2024. While their article’s title mentioned “nearly 100 EVs”, careful reading of the article actually counted 105 EVs. It is important to remember that this article documents only a snapshot in time. In addition, the article omitted some manufacturers with short-term plans to be in the US market, Xpeng for one. Furthermore, many changes to the OEMs’ schedules shown in the article can be anticipated as auto OEMs, in response to pressing financial and supply chain problems and rapidly occurring changes in the US auto market move their development schedules out in time or cancel proposed models altogether.

I have summarized their vehicle numbers as cited in the article below, divided into three categories.

By country of origin, the Automotive News article data breaks out as follows: [Note: Volvo and Polestar owned by Chinese company Geely; UK = Jaguar and Land Rover, made in UK, both owned by Tata, India]

This data shows several interesting points, the most glaring of which is the hybrid release schedule. Why would any auto OEM be bringing out hybrids anymore, especially as late as 2022 and 2023? By definition, hybrids are more complex and expensive than battery electric vehicles and have very limited all electric range. In addition, numerous surveys of plug-in hybrid owners reveal that they rarely charge their vehicle’s battery – continually driving their hybrids in ICE mode! Conclusion: OEMs are bringing out hybrids because they have no all electric alternatives. Furthermore, many auto OEMs are already facing a critical shortage of lithium-ion EV batteries and are thus limited in the number of BEVs they can offer, even if they could develop them quickly enough.

The article contained at least one pickup – Nikola’s phantom Badger – that IMO will never be produced either by GM or Nikola. A total of five other vehicles in the pickup, vans, and delivery group slated for release are from startups Rivian, Bollinger Motors, and Lordstown Motors. While they all have nice prototypes, each of these companies have yet to produce vehicles for sale. Their ability to do so remains suspect. Ford’s all electric pickup won’t be here until 2022! Worse yet, Chevy’s version of same isn’t scheduled for release until 2023! Where have these companies been?

Note that in contrast to Japan – way behind the EV curve, Korea intends to bring out no hybrids. Also note the high number of hybrids from the US and Germany. These reflect not only stopgap measures, but in the case of Germany BMW and Mercedes, strategic blunders and stubborn German obsession with offering any power plant (ICE, battery/motor, or hydrogen fuel cell) of customer choice in the same ICE-designed body/chassis. This is a suboptimal strategy resulting in high cost and complexity, as well as a huge propensity for production line screwups and parts shortages/mix-ups. As or more important, this strategy doesn’t permit innovative engineers to optimize the EV’s design in light of the elimination of ICE related parts and reduced and totally different EV components.

Also observe that after seven years plus of warning that electric vehicles are coming, 60% of these vehicles won’t be coming out until 2022 and beyond if current press release schedules are maintained. To be sure, all electric vehicles are welcome – by environmentally conscious consumers as well as by Elon Musk and Tesla. Few to none of these vehicles will initially, if ever, be competitive with Tesla’s offerings, as we will discuss using the Polestar 2 as an example below.

**** The new Polestar 2 from the Chinese company Geely, that also owns Volvo among other brands, has made a big splash in all its early reviews. As with Xpeng’s P7, the Polestar is a genuinely nice electric automobile. These two vehicles are currently the closest to Tesla’s offerings in the marketplace. First released in Europe, the Polestar 2 is now available through a very few dealers here in the US. US pricing starts at $59,900, and can quickly escalate with various color, wheel, interior and performance options to at least $10,000 above that. US buyers will get a tax rebate of $7,500, lowering the price to a minimum of $52,200. With tax rebate, the Polestar is price competitive with Tesla’s Model 3 and less expensive than Tesla’s current Model Y pricing.

However, the Polestar 2 falls considerably short of both Tesla’s Models 3 and Ys’ ranges, despite having a 78 kWh battery compared to the Tesla’s models’ 75 kWh battery. The Polestar 2 is WLTP rated at 292 miles and just recently at 233 miles on the EPA rating cycle. In one road test the Polestar 2 did 270 miles at a constant 56 mph and only 190 miles at a constant 75 mph. These numbers were about 16% and 22% lower respectively than a Tesla performance Model 3 at those speeds. To some prospective buyers, the Polestar’s many other features may outweigh its range shortfall.

As with any newly introduced vehicle, particularly for new electric vehicle producers, the Polestar 2 has at least one if not two major problems resulting in a recall of the first 2,200 vehicles delivered to customers in Europe and China. The effect of the problem(s?) is that many Polestar 2s have simply gone dead while driving! These Polestar 2s cannot be rebooted and end up having to be towed to a Polestar dealer. Some Polestar’s have been parked at dealers for weeks waiting for Polestar to analyze and fix the problem(s).

According to one article, there is at least one software issue that resulted in Polestar’s safety related recall. However, it appears that there might also be a problem with a “safety device linking the high voltage [battery] and the rear engine [sic!, motor]”. Polestar should have caught these problems in pre-production testing. By doing so, they would have avoided aggravating at least 2,200 customers as well as considerable embarrassment and expense. Fortunately, most early adopter customers have learned to be inured to such teething problems! Tesla, having now produced well over one million cars, has these kind of major quality problems behind them, as its drivetrains and battery management systems are well proven by now, with collectively billions of miles on them.

**** Oh Elon, there you go again! Once again Elon Musk and Tesla have recently moved quickly to acquire significant German engineering talent in one swoop by buying the German EV battery assembly line producer ATW. Not only does Tesla’s act save 210 highly skilled workers’ jobs, but it pulls these workers under its roof just as it is planning to build its own battery production plant at Giga Berlin. This is good public relations for Tesla in Germany. More important, as with Tesla’s previous acquisition of Grohmann Engineering, Tesla no doubt has cancelled any contracts ATW had with BMW and Mercedes. One of Musk’s great strategies is to acquire significant chunks of talent by simply buying a company that already possesses it. Imagine the time and cost necessary to hire 210 skilled people in Germany (or anywhere). Musk wins again!

**** Toyota and Panasonic have announced a joint venture to build a lithium ion battery plant for hybrid cars in western Japan. Starting in 2022! When finished (at least Phase One) it will have the capacity to produce batteries for about 500,000 vehicles a year. Assuming 50 kWh batteries per vehicle on average, that amounts to a 25 GWh annual production rate of batteries. By tomorrow’s standards this will be on the low end of the battery plant capacity scale – a clear indication of Toyota’s strategic timidity and lack of understanding of where the electric vehicle market is going. In addition, this plant is unlikely to be onstream until 2024. Toyota will be building hybrids in 2024?! How quaint!

**** In a previous article I mentioned that some 60% of cars sold in Europe are sold or leased as company cars – perks for employees. A recent article in CleanTechnica cites a study by Dataforce that found that European taxpayers are paying a staggering $32 Billion annually to subsidize polluting ICE vehicles used as company cars. The study urged European governments to end those subsidies and encourage – if not mandate – the use of electric vehicles for company cars.

**** Finally, in case you missed it, Consumer Reports (CR) rather belatedly surveyed its users and found that plug-in electric vehicle owners save 50% on maintenance and repair costs compared to ICE powered vehicles over a 200,000 mile vehicle lifetime. This should not be news to anyone familiar with this blogsite and electric vehicles. In my opinion, this savings may be understated by some 10% to 20%. Hello CR! Nice to have you on board! Their survey will be published soon.

Image courtesy of Pixabay

Your feedback in the form of comments or suggestions are welcome in the comment window. Thank you for following my blogs on this site and for participating in my blogging community.