In a previous blog, we mentioned one of Elon Musk’s credos: “The best part is no part.” Or, why utilize several separate parts when one integrated part, say a metal casting or plastic molding, is better. Minimizing parts counts is one of the keys to the continual improvement (kaizen) effort that Musk has established as gospel at Tesla.

Elon Musk may have learned the wisdom of parts count minimization during his years in South Africa where he was no doubt well acquainted with British autos – Land Rovers, MGs, and Jaguars, and perhaps British motorcycles too. British automotive and motorcycle design engineers were not keen on continual improvement in the sense we understand it today. Always short on funds to develop new parts, it seems they designed with a goal of parts maximization, not minimization.

For decades, Land Rovers produced in its Solihull, UK plant were at the very bottom of motor vehicles’ quality ladder.

Triumph and BSA motorcycles went from one set of points and an ignition coil on their single, to two sets of points and two coils on their twins, and three sets of points and three coils on their triples! All this instead of designing a proper distributor on the twins and triples that required only one set of points and one coil.

There were models of MGs that had three windshield wipers driven by three wiper motors across their not very wide windshields!

Jaguar XJ6s (at least) had two fuel tanks and two of the Devil’s vilest contraptions – Lucas electric fuel pumps!

No wonder in their original incarnations these British companies all went broke! Ah, but I digress……now a return to the world of battery-powered electric vehicles and the future.

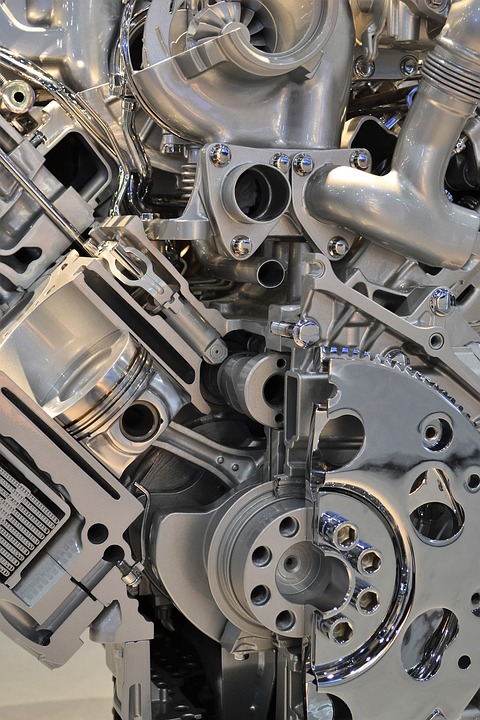

As we stated in that earlier blog, one of the key advantages of battery-powered electric vehicles over internal combustion engine (ICE)-powered vehicles is their dramatic reduction in parts count and complexity, leading to equally dramatic cost and production time savings. A familiar statistic that is often quoted is that an ICE-powered vehicle has 2,000 moving parts in its engine (one version) or engine/transmission (another version) and a battery-powered electric vehicle only has 20 moving parts in its motor/drive unit. Maybe, but in the real world of engineering, manufacturing, and supply chain management, it’s a bit more complicated than that.

Let’s start by noting the not-so-subtle apples versus oranges comparison of “moving parts” to parts. A part is a part. Whether it moves or not is irrelevant to rigorous parts count comparisons. The distinction does matter to design engineering, for moving parts have many more engineering challenges than stationary ones – – matters such as kinematics, dynamics, the possible need for gears and/or bearings and/or lubrication, and so on. Moving parts are generally more expensive as well.

For valid parts count comparisons, it’s critical to note whether one is comparing parts as a total parts count, or as a stock keeping units (skus) count. An sku is a unique part and therefore not interchangeable with any other part. For instance, a conventional V8 auto engine might have twenty screws that secure its oil pan to its block, but those twenty fasteners are (or should be, from a design viewpoint) identical — just one sku. So when “parts” are ambiguously defined, is the count one or twenty? Consistency or apples-to-apples comparisons matter; either skus to skus, or total parts to total parts.

Let’s consider a simple example of skus and part counts – the two cylinder heads of a 4 valve per cylinder pushrod V6 engine (common design):

It obvious that the parts count can add up quickly, even if the number of skus is minimized, depending on the overall complexity of the design – 4 cylinders, 8 cylinders, etc. Furthermore, all the accessories that are added externally to internal combustion engines really raise the parts count – brackets, belts, hoses, pulleys, A/C compressors, power steering pumps, etc.. Don’t forget the “rear” necessities too – exhaust pipes and sensors, catalytic converters, tailpipes, and various hangers and brackets.

Electronics really complicate the parts count issue. For example, consider the several circuit boards that are inside the inverter that is a part of a Tesla motor/drive/inverter unit. [This inverter changes the battery’s direct current (DC) to three-phase alternating current (AC) that powers the motor.] Each of those circuit boards may contain hundreds of items such as tiny capacitors, diodes, resistors, semiconductor chips, and tiny heat sinks, for instance. But since these circuit boards are quickly “stuffed” and soldered almost totally by highly automated machines, it makes sense to count each circuit board assembly as one part.

From a cost-saving viewpoint, both skus and the number of parts used of each sku count, though in different ways.

Minimizing the number of skus on the production floor saves on inventory space and the variety of automated production and robotic tooling necessary to install each sku. Similarly, minimizing skus reduces required operator training and the chance of operator error in selecting the wrong sku.

In many ways having a high parts quantity each of each sku is the lesser sin, as the same tooling (whether automated or hand tools) and operator (if needed) skills can be used for each individual item of an sku. As we’ll discuss in a bit, this lesser sin also pays dividends in other cost reduction and complexity areas.

The part count per sku impacts production time on the shop floor. Obviously, it takes more time and therefore costs more to install ten screws rather than four, unless you are using state -of-the-art and very expensive automation that would install (and tighten equally) all screws concurrently.

In judging the impact of sku or parts count reduction on a manufacturing company, it’s the sku count that is the organizational killer.

Continued in Part Ways with Your Parts (Part 2)

Image courtesy Pixabay

Your feedback in the form of comments or suggestions are welcome in the comment window. Thank you for following my blogs on this site and for participating in my blogging community.

One Response

Great article Tom… It really shows how long term the EV car should be significantly cheaper to produce and maintain.